Ji-Tech Industrial Company

Engineering Team

Of

Noodle Production Lines

Company Profile

Machine Prices

Machine Descriptions

Production Line

Lay - Out of Production Line

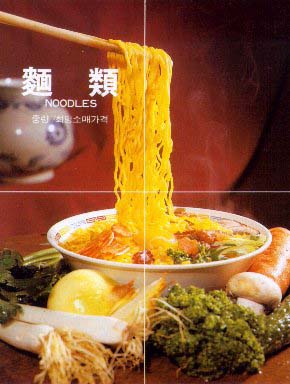

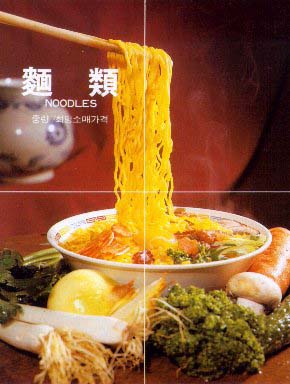

Noodle Products

How to contact us

Company Profile

Foundation

: Engineering Team - September 1961,

Trading Team - 23 September 1997

Main Product: Instant Noodle, Dried Condiment

Soup & Machinery

Scope of Supply : Export instant noodle, Dried

Condiment Soup, Production Line of Instant Noodle & Dried Condiment Soup, Machine Design, Machine Manufacturing, Product Guaranty, Product Training

Machine Prices (Whole Line)

Descriptions of Each Model

- Model Ji-BAG-720

Product Capacity: 102,000~128,000 pcs/8hrs

Electric Power Consumption: 159.15kw

Steam Consumption: 2,700 kg/hr

Water Consumption: 40 Ton/day

Man Power: Male: 7, Female: 19

Building Area: 2136m2 (12m * 178m)

Product Weight: 85~120grams

(Noodle: 80~110grams,

Dried Condiment Soup: 6~10grams)

Model Ji-BAG-360

Product Capacity: 51,300~64,120 pcs/8hrs

Electric Power Consumption: 109.05kw

Steam Consumption: 2,400 kg/hr

Water Consumption: 30 Ton/day

Man Power: Male: 7, Female: 11

Building Area: 2136m2 (12m * 178m)

Product Weight: 85~120grams

(Noodle: 80~110grams,

Dried Condiment Soup: 6~10grams)

Model Ji-BOWL-720

Product Capacity: 95,700~102,000 pcs/8hrs

Electric Power Consumption: 216.3kw

Steam Consumption: 2,800 kg/hr

Water Consumption: 40 Ton/day

Man Power: Male: 10, Female: 26

Building Area: 2136m2 (12m * 178m)

Product Weight: 65~86grams

(Noodle: 56~74grams,

Dried Condiment Soup: 9~12grams)

Model Ji-BOWL-360

Product Capacity: 35,900~38,480 pcs/8hrs

Electric Power Consumption: 141.7kw

Steam Consumption: 2,000 kg/hr

Water Consumption: 30 Ton/day

Man Power: Male: 6, Female: 22

Building Area: 2,136m2 (12m * 178m)

Product Weight: 65~86grams

(Noodle: 56~74grams,

Dried Condiment Soup: 9~12grams)

Production Line

Lay-out

Each Part of Production Line

Dough Mixer

Dough Feeder

Dough Roller

Rolling Machine

Slitter

Steamer

Auto Fryer

Cut and Folding Machine

Conveyor

Cup Filler

Auto Packer

Process Lay-out

HOME

How to contact us;

Mailing Address:

#103~104, 453-3, Shinchun-Dong, Shiheung-Si, Kyonggi-Do,

429-020, Korea

- Contact

Korea ; Mr. Jungil Oh

Tel: +82 32 695 81 91, +82 11 90 33 85 01, Fax: +82 32 695 76 44, E-mail I.D: jitechind@netsgo.com

U.S.A. ; Mr. Leo Moon

Tel: +1 562 422 8699, Fax:+1 562 423 3673

Italy

; Mr. Sergio Colombini

- Tel & Fax: +39 293 290 190, E-mail I.D: csmco@tin.it

- P.R. China

; Mr. Berlin Zhang

Tel: +86 532 587 8591, E-mail I.D: berlin@qingdao.cngb.com

For more detail questions, Please E-mail jitechind@netsgo.com

HOME

HOME

![]()